Everything about tea making and blending processes

Jan 28 2018 Tea History

Tea continues to be the world’s most popular beverage as its global consumption exceeds the combined intake of alcohol, coffee, carbonated and soft drinks, and chocolate drinks. The consumption of tea can be traced back to Southwest China about 3 millennia back where the beverage was taken as a prophylactic drink. Mankind has come a long way since then, and one good way of gauging the evolutionary progress is by reviewing the different ways tea plant is cultivated and the beverage is consumed the world over.

It is important to mention right at the outset that soil texture, climate, and altitude have a bearing on the liquor color and flavor of a particular strain or variety of tea. Once the cash crop is ripe for harvesting, processes applied for blending varieties grown in diverse areas and brewing the same to make a considerable impact. Taking into account that presently about 1,500 different strains of ‘camellia simensis’ (the scientific name of tea) are harvested in nearly 36 countries you’d be simply spoilt for choice when it comes to blending some choice varieties.

All the varieties of tea plants that are grown throughout the world can be grouped into six distinct categories namely: white, black, green, oolong, flavored, and compressed teas.

Going back to basics: The Tea Factory & Processing of Black Tea

Tea leaves are plucked from gardens using the ‘two leaves and a bud’ technique where only the first two leaves and the bud are handpicked, leaving the 3rd and 4th leaves intact. It is a very specialized technique and might take a long time to perfect. Plucking the leaves using this process is crucial to ensure that the natural antioxidants and flavor is retained as picking the last two leaves would make the beverage taste extremely coarse and bitter.

Once the plucked leaves are deposited at the factory, these are spread evenly on large trays or racks. Thereafter, the racks are placed on shelves that are quite a distance from the ground in order to expedite the withering of the leaves. The tea leaves shrivel perfectly when the indoor temperature is maintained at a range varying from 25˚C-30˚C.

The shriveling process where the leaves lose moisture can take anything from 12-16 hours. Factories make use of desiccators or blowing fans for speeding up the mechanism, especially if the environment tends to be vapid. After the leaves dry up fully and become shriveled, they are pulverized by machines resulting in the release of natural juices which in turn absorb oxygen from the air and become oxidized.

The mincing is carried out using two kinds of machines-‘orthodox’ machines and ‘unorthodox’ machines. The terms actually signify the breaking up technique used by the specific machine. In the orthodox process, the machine rolls up and tears the leaves into sizable particles or pieces that are called grades.

As far as the unorthodox process is concerned, two different sorts of machines are pressed into service. The first type crushes, tears, and curls the leaves into small pieces, much smaller than those done by the orthodox machine, and hence the tea leaves crushed by the former are known as CTC varieties. The other type of unorthodox machinery, called the Rotovane machine, also crushes the leaves into tiny fragments.

The whole idea of breaking down the tea leaves into smaller pieces is to create varieties that can be brewed quickly, thereby enabling people to drink their favorite beverage without having to wait too long. After the leaves have been minced thoroughly, these are yet again spread out on large troughs. But this time, the trays are kept in a humid and cool environment to facilitate oxidation or fermentation.

The leaves are mildly turned over at frequent intervals all through the oxidization period. You know that the fermentation is complete when the leaves take on a golden russet hue and thereafter they are fired so that they dry up fully. For drying, the leaves are made to pass through compartments of hot air that sucks up the moisture content and now the leaves have a blackish or dark brownish appearance.

After the desiccation is over, the deep brown or black colored leaf pieces are carefully emptied out of the heat chambers and put into large chests. Thereafter the leaves are segregated into separate bundles according to their sizes for which they are passed via numerous meshed sieves, each having a distinct pore size. The separated heaps of leaves having different sizes are poured into containers following which chests or cartons are packed with the same and sealed hermetically for stacking onto pallets.

The pallets stacked with several such tea chests are transported by forklift trucks to warehouses and stockrooms where these are stored before being dispatched to their final destinations. Tea-estates employ tea-tasters who sample the different varieties just to make sure that the leaves have not been tainted or polluted by contaminants inside the factory. Brokers all over the world receive samples of the strains and they taste the varieties for assessing the quality and determining the prices to be charged.

The factories are scrupulously washed and cleaned after every manufacturing cycle so that the subsequent processing cycles are not adversely affected by any residual contaminants or pollutants.

Processing of Green Tea

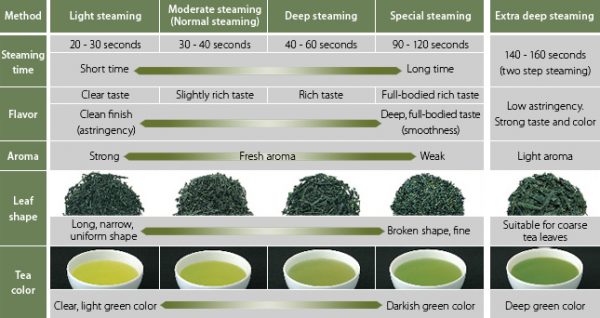

For preparing green tea varieties, the shriveled leaves are fully steamed and turned over before these can be fired. Extreme care in steaming and rolling the leaves so as to check the leaf veins from cracking that might lead to their oxidization. After brewing green tea where the soaked leaves are not stirred or broken, the liquor color is remarkably pale.

Green tea is popular in some countries of South America, Japan, and China.

Processing of Oolong Tea

The processing method of oolong tea is quite identical to that of black tea only the oxidation window is much shorter, approximately 1-2 hours. Owing to its reduced fermentation process, oolong tea is also known as semi-fermented or semi-green tea. Oolong tea leaf pieces are mostly of the orthodox variety and is typified by their gentle flavor and pastel yet bright liquor and best had without adding milk.

Processing of White Tea

Meticulous care is taken while picking off the leaves for white tea, where the fresh buds are yet to bloom. The plucked leaves which are quite tender are subjected to an extended withering process to enable the leaves to be fully dehydrated before these are made to pass through hot air chambers. The twisted and whorled leaves assume a silvery look and texture.

Processing of Compressed Tea

The compressed tea making process entails heavily steaming bunches of the green leaves, squeezing the steamed leaves in the form of bricks, and then letting the bricks dry up. It is the Chinese who are credited with first using this tea making process. Nowadays, compressed tea is available as balls, bowls, and layered cakes.

Blending of Tea

About 90% of the tea varieties that are sold in the UK happen to be brands that are prepared by concocting or blending up to a maximum of 30-35 distinct varieties. These brands are highly sought after by those who struggle to start their day without first having their morning cuppa, and are easily available in most shops and supermarkets. The blended brands are popular because of their consistency with respect to flavor, character, and quality.

Each and every blended tea brand is prepared using a recipe that is unique and exclusive. Companies that own and market their brands are fiercely protective about the recipes and would go to any length to keep the formula a trade secret. The tea blender who has extensive experience of tasting teas is responsible for ensuring the blend(s) of his or her firm satisfies all quality parameters.

Therefore the tea blender or tea taster will sample the teas that his company has purchased from the auction house where tea chests arrive from tea leaves processing factories.

For more content by Tea Lovers, click here.